KATA – The spectacular successes of Toyota Motor Corporation, which have been repeatable for decades, as well as its adaptability, continue to evoke admiration and interest from manufacturing and service companies around the world. The source of these successes is the most famous and copied production system in history (TPS), which has become the basis of the lean manufacturing system. It turns out, however, that the direct copying of production management tools and techniques, without logic and methods of managing people, does not even give the slightest chance for improvement, better results, and for the survival of the organization in the long run. Therefore, are we copying “the right things”? This article will answer that question. This is the beginning of our series concerning “kata”.

Toyota Production System – History

The Western world became seriously interested in Toyota in the late 1980s, when a still little-known and underestimated Japanese company unexpectedly began to be an increasingly competitive player against the largest American automotive companies on their own market. It was the beginning of the period of the biggest automotive icons – the so-called Detroit Big Three (Ford, GM, Chrysler) – constantly losing with Toyota and their new adaptive lean manufacturing concept. As a result, the process of “mass lean” began very quickly in most Western companies, which, to this day however, has not brought the expected business results. This is because “becoming lean” is treated only as a process of implementing the TPS toolkit (e.g.: 5S, kanban, SMED), and takes place without the necessary deep cultural change – especially methods of leading people towards kaizen. They are components of Toyota’s second key system: Total Quality Control (TQC). By the way, for decades 70-80% of changes, transformations, and restructuring of enterprises have failed, because production tools and processes are more important than people. Toyota reversed these proportions by strongly focusing on employees. And only then did it start…

Two concepts of TPS

Every great change is always preceded by an inspiring vision that creates development and strong leadership. When they are accompanied by important and urgent needs, unusual solutions usually emerge (“necessity is the mother of invention”). The history of Toyota is the best example of this, and can be an inspiration for any manager, in any company, regardless of the place and industry. The vision of Toyota Motor Company founder Kiichiro Toyoda (1894-1952) was to “become the world’s leading automotive company.” At a time when Toyota’s efficiency was about 10 times lower than the average efficiency of the Big3 from Detroit (1951), it was a very bold challenge that required consistent effort. The saying: “a vision without implementation is a hallucination” could have been most accurate in this situation and time. After several decades, we already know that the vision has been implemented and that the key solutions have proved to be successful.

Rationalization – Production System (TPS)

The first and most important step on the path to the vision was to face the enormous barrier for the development of any manufacturing company in Japan. It is the lack of natural resources and the related need to incur high import costs. Toyota has found strategic solutions to this problem by systematically rationalizing the remaining cost items, especially production costs. The elimination of all waste has become an obsessive necessity and the source of the TPS (lean manufacturing) system.

Competitiveness – People (TQC)

The second key factor behind Toyota’s business concept and its exceptional competitiveness is the providing of better-quality products with higher added value than other automotive companies. For comprehensive quality control, the TQC system that is awarded with the Deming medal is used, and it mainly consists of human aspects (employee behavior in processes). It is thanks to the full use of the potential and skills of employees (especially in solving problems) that Toyota builds competitiveness and continues to be an unrivaled model of continuous adaptation, quality improvement and cost competitiveness.

Toyota Production System Concepts – Conclusions

It should be emphasized that Toyota’s approach is a combination of two TPS and TQC systems, which relate to production management (processes) and people management (behavior), respectively. Toyota believes that both systems have a similarly high impact on the company’s competitiveness (TQC – even higher) and that they should not be separated. Unfortunately, the realities of the “non-toyota” companies (also in our country) show that significantly more attention is paid to the TPS system, with human aspects being neglected.

It is worth paying attention to the statements: “We treat employees as people and with respect” and “we build a system of respect for a human, in which employees can present all their skills by actively participating in maintaining and improving their workplaces…” For people outside of Toyota, this may sound like a motto or advertising slogan, but for Toyota’s employees it has a deep meaning, great value, and is associated with responsibility and obligation. These are very important elements of organizational culture and the company’s DNA.

Treating employees “as people” and with “respect”

The adoption of the “human” factor of the concept had (and has) serious implications, especially in the attitude to employees, in the transformation of organizational culture, and in changing the type and role of a leader. Treating employees “as people” and “with respect” means changes, including in particular:

- the need to improve the level of the employee-supervisor relationship. From being treated instrumentally (1 – a “transactional” level of the relationship – the employee is a “cog in the machine”), we should move to be treated subjectively (2 – a “partner” level – the employee is a “person”). Superiors who build self-esteem using power do not fit into the new culture in which the role of the superior is reversed (“servant leader” vs. “served”). The so-called “clan” type of culture (or “collaboration”), in which the feeling of stress disappears, begins to prevail, and commitment and greater input into all tasks are triggered (the so-called Hawthorn syndrome). We can talk about a family atmosphere, loyalty, pride in belonging to an organization, and a generally higher sense of well-being.

- respecting people means, among other things, recognizing their dignity, values, potential and possibilities. Therefore, superiors should give employees more freedom in action (instead of controlling them), set new ambitious goals, and methodically support them in their implementation.

- the role of the supervisor is radically changing: from a “manager/supervisor of the implementation of tasks”, a leader becomes a “teacher-mentor”. Because in Toyota: “to manage is to teach”, i.e. to develop the skills of employees, who then improve processes using proven methods – patterns of thinking and acting (kata).

What is Toyota Kata

Psychology professor Daniel Kahneman, winner of the Nobel Prize (2002) in Economics for his discoveries that challenged the rationality model of human judgments and decisions, explains that two systems determine how our thinking works:

- “System 1” is our intuitive “automatic pilot”. It works very quickly, it is habitual (“second nature”) and emotional. It is effortless and requires no attention (control), and it is enough for us in routine circumstances (on average 90-95% of situations in life).

- “System 2” divides our attention between activities that require mental effort, such as problem-solving. It is definitely slower, but is rational and logical. System 2 is activated only when system 1 has difficulty with a task. System 2 is responsible for innovation, however, it requires concentration and consumes a lot of energy. For this reason, we usually intuitively avoid new challenges, even though we have great potential. According to Toyota, this is the greatest “eighth waste.”

It is worth asking the following questions: “What would happen if our rational (based on a scientific pattern), and not intuitive way of thinking, thanks to which we can solve problems and create innovations every day, ceased to be a choice and became our” automatic pilot ” – ” second nature “? What if this ability is applied to all employees in the organization?

There is only one answer to these two questions: we would be dealing with a “kata”, which will surely result in unique features and culture, and the successful fate of the organization and individual employees! Recent scientific research clearly shows that the success of an individual is much more influenced by the environment (“classroom full of talented students”, “company full of talented employees …”) than the IQ of the person itself.

As you can easily guess, changing the nature of a person and their intuitive and atavistic patterns of thinking and acting is not easy – it requires new desirable patterns and natural leadership, which is itself a change.

Toyota Kata Book

Mike Rother, in the excellent book:

Toyota Kata. Managing people to improve, acquire adaptability, and achieve above-average results, identifies and describes the two most important management patterns (TQC elements) that are key for changing schemes, employee development, and for achieving success by the entire organization:

- Improvement Kata

- Coaching Kata

They are the most important habits of any superior and, as “second nature”, are automatic (and reflective). In our opinion, the use of the word “kata” by the author is an accurate metaphor that places the described management practices in a more meaningful and richer context. “Kata” has many meanings and cannot be described unambiguously.

Kata Meaning

“Kata” is derived from the basic sequence of movements (standard form) performed in martial arts. It is passed down through generations from master to student. In practice, learning is based on experience: the teacher demonstrates and corrects the student. There is no theoretical learning (from instructions).

Due to the constant practice of kata (repeating patterns many times), people are more self-aware and self-confident. This is of great importance when meeting any challenges.

Kata and Shuhari

“Kata” is a learning cycle: shu-ha-ri. Shu – protect (TWI training + supervision), ha – break away (supervision), ri – freedom to create (the student already has good habits and improves himself with the support of a coach). This cycle represents three stages of learning for a student and three levels of commitment for a teacher. Important note: in “non-Toyota” companies, the employee training cycle usually ends at the “ha” stage, when a student begins to reflect the applicable standard, and the instructor ceases to supervise him. This often happens before the employee becomes familiar with the task and before developing a desired habit. At Toyota, each employee’s learning cycle continues throughout their working lives. The learner goes through all the cycles over and over, and deeper and deeper – periodically going back to the basics. Going back and refreshing the basics elevates the skill to a higher level (master practice). Thanks to this, each employee improves, and at the same time improves the applicable standard. Taiichi Ohno once said: “a person who has not made a single improvement in standard work within a month does not deserve his salary.”

Improvement Kata

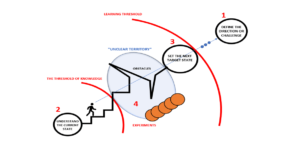

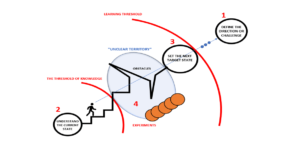

The improvement kata mainly involves patterns that bring out and develop the natural human ability to solve problems and improve. Their goal is to solve problems, and at the same time develop people. In other words, they are the patterns that determine how to continuously improve and adapt to a changing environment. But it is not everything. They are also a way of managing people on a daily basis. The improvement kata is practiced at all Toyota levels and consists of four stages:

- confirmation of the vision or direction of action,

- understanding of the current conditions (current situation),

- determination of the closest target state (next challenge) on the way to the adopted vision,

- striving for the target state by quickly repeating PDCA cycles in order to find and remove obstacles.

Improvement Kata and PDCA

It is worth paying attention to the importance of the PDCA cycle – the foundation and part of the TQC. Toyota has modified the conventional PDCA model to continuously increase quality and productivity. The cycle is based on a scientific method of proposing changes to the process, implementing these changes, monitoring and measuring results, and taking corrective actions. It is used in solving all kinds of problems: from spontaneous (troubleshooting, elimination of deviation from the standard) to caused (reaching the target state, introducing innovations) problems.

Fig. 1 Improvement KATA Source: Mike Rother

The more short PDCA cycles there are, the more learning there is. Thanks to their application, Toyota has developed its learning organization in an extremely pragmatic way. Its success is mainly because employees very early recognize problems at the process level when they are still minor and easy to solve. Behind this is their habitual ability (kata) to act effectively, not only in standard and predictable conditions, but most of all when faced with a completely new situation and problem. The improvement kata should only be used when an employee has sufficient potential for further development (is instructed, feels confident, and has been included in the standardized work-stage ri), is aware of the approach to continuous improvement, and can apply the pattern.

Even though the improvement kata is a very universal and effective routine, it cannot be expected that it will be implemented on its own in the entire organization, and become a common habit (part of the culture). It is worth noting that its use is not intuitive, and requires long learning and constant support by an experienced teacher (sensei, coach). This is what the coaching kata is for.

Coaching Kata

It is a humble and patient way of teaching and applying the improvement kata correctly, which takes place through the teacher-student dialogue. This is similar to the traditional approach to the learning process, which involves practicing a profession under the guidance of a master (coach). However, it is worth paying attention to a few important elements that are characteristic for the Toyota model:

- The need for coaching never disappears as it is impossible to become fully proficient in the application of the improvement kata.

- The teacher-student relationship is based on real respect and trust.

- At Toyota, every employee has their own coach. Each employee is assigned to a more experienced employee (mentor) – in the case of an operator, this is a team leader, who in turn is supported by the group leader. At higher levels, it is not only the immediate supervisor that can be a mentor.

- A coach must meet high skill requirements. Teaching can only be done by a person who has a very conscious approach to continuous improvement, the ability to use the improvement kata, and the ability to teach it (coaching kata).

- One of the most important skills of a coach, apart from the use of PDCA and the A3 report, is A3 thinking. This report is a method that combines two important management processes: hoshin kanri (strategic management) and problem solving.

- The role of the coach is not to share their knowledge (solutions) with the student so that he or she is able to cope with the challenge faster and more effectively. This is a very common mistake in many organizations and causes learners to “take shortcuts” in order to avoid the tedious process of learning by doing. As a result, this may lead to a short-term improvement in efficiency, but it will not enable people to truly understand and master skills. Therefore, first master the first step, and then move on to the next one.

- During the dialogue, the mentor helps the learner understand, but the learner has to come up with the solutions himself. For this purpose, the mentor even allows for small mistakes to be made (but without affecting the client).

- The coach is responsible for the results of the process (the motto from TWI: “if the student has not learned, it means that the teacher has not taught”)

Summary – Kata

Toyota’s business success comes from two systems: the very popular and successfully implemented production system (TPS), and the less-known Total Quality Control (TQC). The second system largely concerns leading people, and more precisely with their constant involvement in improving of their skills through

problem-solving (from faults to innovations). Development of people and continuous improvement of processes are the top priorities of each superior, who is best defined by the word “mentor”. Daily, he uses proven methods of management, including, above all, two patterns of thinking and acting (habits, and routines), i.e. the improvement kata and the coaching kata.

These are the elements which, in our opinion, are the missing link in most Western organizations (including Polish ones), and which prevent their further development. These are the “right things” that absolutely must be dealt with, because everywhere we deal with employees, and also with a greater or lesser waste of their potential.

It is worth noting that the systems, and even Toyota culture, are based solely on Western concepts (or rather their elements), which were then tested, adopted, and improved (such as Taylorism,

TWI Program, TQM, human relations trend). These solutions are culturally familiar to us and it is worth taking advantage of them.

Source:

Production Director at Turbo-Tec Sp. z o.o. He has been working in the production industry for over 25 years, most of which

in the automotiv industry. Manager at Toyota Motors. Lean Specialist, Coach and Mentor of Kata. AGH UST graduate

Krakow and the Warsaw School of Economics. Privately, an enthusiast and user of Harley Davidson motorcycles.

Over 30 years of experience in Lean Management. He is a psychologist, consultant, trainer, coach and management mentor. He was a Regional Director in leading organizations in the financial industry and participated in the creation of HR and management projects implemented jointly with the consulting BCG Company. Specializes in the development of people, leaders, teams and organizations in the VUCA environment.