What is Job Onboarding? The implementation of direct production employees is conducted in a slightly different way than onboarding for administration employees. Here, on-the-job training are the most important, as they are meant to introduce the employee to working in a quick, effective, and safe way. In the era of rising costs, enterprises do not want to spend additional costs on employing new staff members too soon. Most often, it is the customer’s situation that determines such a decision. A sudden increase in orders means that there is a sudden shortage of manpower. In turn, uncertain times have shown that as soon as these orders arrive, they can drop quickly, which may result in some staff members not being used effectively.

Of course, the employment liquidity ratio should be analyzed in the long term to avoid sudden drops or increases in recruitment needs. Nevertheless, I know from my own experience that companies do not want to spend too much time on the training process, because, as you know, time is money … The key here is to show a new employee how to operate a given machine in an effective manner (production standards), which is by the requirements of customer quality standards and company standards, while at the same time maintaining security measures. However, what often seems simple and logical to us – experienced employees – will not be the same for a new person who may be standing in a production hall for the first time, where the culture and standards of work differ significantly from what they know. Therefore, it seems that it is a significant challenge to effectively find an employee for a particular workplace and to implement the employee proactively.

Table of Contents

ToggleStructure of the job onboarding

Onboarding training can usually have a theoretical part, during which employees are introduced to basic elements such as health and safety requirements. Moreover, during sessions with the HR department, they sign employment documents and an employment contract, and also learn about the organizational scheme of the company and department, as well as the profile of the organization. They learn what the organization does, and what its values, goals and visions are. They become familiar with the standards in force in the plant. They undertake training on the quality of manufactured products, as well as customer requirements. At the end, they learn about all the tools for effective work, such as TPM, 6S standards, Work Instructions, control cards, and procedures supporting the production process. The second stage of the training is the practical part, where the employee receives on-the-job training.

Generally speaking, the above elements should prepare an employee for effective work. Nevertheless, reality shows that onboarding conducted in such a scheme is not effective. Why? Because the employee is overwhelmed by the excess of information he receives … An eight-hour monologue during the theoretical part, despite the best efforts of the instructors, will not be effective. As research shows, full focus takes about 15 minutes. After this time, a person involuntarily turns off their concentration. Therefore, if we want to achieve full integration with a trainee, it is worth combining theory with practice … But how to do this?

The fundamental element is an appropriate consideration and planning of the training process, because, as other research shows, the time, effort and money spent on recruiting a new employee may be wasted by a poorly conducted process or the lack of an onboarding process. This is one of the causes of staff turnover.

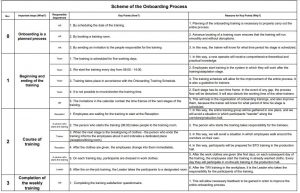

Effective job onboarding is conducted in stages

The entire process can be broken down over a period of one week. This is the minimum time during which an employee will receive from the employer knowledge, work tools, and the necessary support and care, which at such an early stage will determine the decision of a newly employed person to become a member of the new community or not. This will be the first step.

The second step should involve the planning of trainings. Planning means defining the training schedule, while taking into account different topics, informing responsible people, and indicating the training time (preferably planning in the outlook calendar). It is very important to treat the process of introducing new people as a project that is meant to bring the company tangible profits. I have often encountered situations in which people who are responsible for various stages of the training forgot about it … either due to the lack of adequate information, or having too much of their own work. They did not feel the importance of this process. Unfortunately, this approach has a negative impact on the entire organization.

Example of the job onboarding training

This approach will allow a new employee to walk through the training process in a structured manner.

Job Onboarding SOP

It is worth combining the theoretical parts with practice here. This will allow new employees to better understand the topic. Some examples of how you can increase engagement and employee activity are presented below:

- OHS game – all the hazards that an employee may encounter during his work are presented on a board. The task of the participants will be to guess these hazards and discuss why they are dangerous. Whoever finds the most discrepancies is the winner.

- 5S game – jumble. The participant’s task will be to match sentences and statements with the appropriate “S” from this tool. For example: I put a hammer to the tool cupboard. I throw away garbage to the marked bin. I turn off the light when I leave my workplace. I tell off a colleague who destroys equipment.

- Quality game – we show participants the products that are manufactured in a given organization. However, the presented products are NOK. They will also receive the master copy. The task will be to find defects.

- Production game – work sample. Participants in the qualitative training can try to do simple work that will be part of their later tasks. The test must reflect the real process, but simple enough for an employee to build a sense of being able to do things, e.g. tightening elements with the use of appropriate equipment, product quality measurement, filling in production documentation, or ordering material from e-kanban.

In this way, we teach employees to behave in the right way and meet applicable standards, but also influence their awareness through commitment. Thanks to work samples, we reduce the risk of the frustration or fear of not coping with real production conditions.

On-the-job onboarding training should also not constitute one long training cycle, and they should be divided into 2-4 hour stages, where a dedicated Instructor, i.e. an experienced employee, will conduct such training. An appropriate approach to this stage will also result in the employee’s later effectiveness. Here, again, I will support my statement with the results of previously carried out research, which says that well-conducted on-the-job training improves the productivity of a new employee by over 50%. One of the best approaches to on-the-job training is the TWI training method, which guarantees that the trainer will provide all the required information to the trainee, and the trainee, by repeating and discussing the presented activities, will quickly learn how to do the job correctly, safely and consciously.

Onboarding and TWI

TWI onboarding training mean that an employee is better prepared for work, and combining them with elements that they heard during the theoretical part will allow for self-reflection and will encourage employees to ask questions. For example, when we discuss the TPM tool, the participant realizes during the game what elements he may encounter in production. Then, during the on-the-job training, he observes how experienced operators check whether the machine on which they will work is checked, and performs subsequent control elements in accordance with the TPM card. The trainer himself then has the opportunity to check the operation of e.g. sensors. Practice teaches, develops and builds awareness.

The final stage of employee training should be collecting feedback from newly hired employees regarding their reflections and comments, if there are any. A good approach is to use a questionnaire that includes the most important issues for us regarding the preparation of the training structure, the preparation of trainers, instructors, materials or training conditions, as well as for getting to know the feelings of employees in relation to the entire project.

During several years of conducting onboarding training for production employees, I have learned that the TOP3 elements that employees appreciate the most are:

- an appropriate work atmosphere and the calm approach of the Instructors to on-the-job onboarding trainings – this allows the stress associated with a new, yet unknown process, to be reduced,

- dividing the transfer of knowledge into stages, which allows for a better understanding of work,

- involvement of the training team, which shows that the company cares about a new employee.

Summary

Over 10 years of experience in the production processes. Responsible for Training WIthin Industry and Onboarding processes in Automotive Industry for over 6 years. Now she is working as a Lean Manufacturing Trainer for MAN Bus and Trucks.