Value Added vs. Non Value Added are key concepts in process improvement methodologies, particularly in Lean Manufacturing and Six Sigma. Value Added (VA) activities are those that, in the eyes of the customer, enhance the product or service, making it worth more or more desirable. On the other hand, Non Value Added (NVA) activities are processes or steps that take time, resources, or space but do not increase the product’s value. Identifying and minimizing Non Value Added activities while enhancing Value Added ones is crucial for increasing efficiency, reducing waste (muda), and improving overall customer satisfaction. One of the easiest ways to achieve improvement is to eliminate Non Value Added activities from your process/job. You don’t need special skills and statistical tools for this, in many cases is enough just to be rational & logical. Non Value Added activities are always around us, but we are too blind to see them.

Table of Contents

ToggleThree groups of activities

In this chapter, we delve into the classification of activities in any operational process, breaking them down into three fundamental categories: Value Added (VA), Necessary Non-Value Added (NNVA), and Non-Value Added (NVA) activities. This framework is essential for identifying areas for improvement and increasing efficiency, particularly in sectors such as manufacturing and services, where the optimization of operational processes can lead to significant cost savings and better customer satisfaction.

Value Added (VA) Activities

Value Added activities are those that directly enhance the value of a product or service from the perspective of the customer. These are the activities that the customer is willing to pay for because they contribute to the transformation of raw materials or services into something that meets their needs or desires.

- For example, in manufacturing, VA activities include processes such as cutting, machining, assembling, or painting. These actions physically alter the product, turning raw materials like steel sheets, plastic, or wood into a finished good, such as a car part or a piece of furniture. The customer perceives these activities as necessary to the creation of the final product and is willing to cover their cost.

- In service industries, VA activities are slightly different but still focus on delivering something of tangible benefit to the customer. For example, in a hotel, cleaning a room or serving a meal are Value Added activities. These actions directly impact the customer’s experience and are integral to the service they are purchasing.

Necessary Non-Value Added (NNVA) Activities

Necessary Non-Value Added activities are those that do not directly contribute to the value of the product or service, but are still necessary for the process to function. Although the customer does not perceive any additional value from these activities, and they are not willing to pay for them, these steps are often unavoidable due to technical, regulatory, or safety reasons.

- For instance, in manufacturing, NNVA activities include things like inspection, quality control checks, and the transportation of materials within the factory. While these activities do not physically change the product or enhance its value from the customer’s perspective, they ensure the product meets quality standards, complies with legal regulations, or functions within the manufacturing process. Without these steps, the risk of defects, customer dissatisfaction, or regulatory penalties increases.

- In service industries, an example of NNVA activities could be the time spent entering data into a system or preparing documents for regulatory compliance. While the customer doesn’t directly benefit from these tasks, they may be necessary to maintain operational efficiency, legal compliance, or safety. For example, airlines must perform detailed safety inspections before every flight; though customers do not pay specifically for this activity, it is crucial for ensuring safety.

Non-Value Added (NVA) Activities

Non-Value Added activities are tasks that do not add any value to the product or service and are not required for the process to function. These activities add unnecessary time, cost, or complexity to the process, and should be minimized or eliminated wherever possible. Customers are not willing to pay for these activities because they do not contribute to the final product or service in any way.

- Examples of NVA activities in manufacturing might include waiting times due to machine breakdowns, reworking or repairing defective parts, or searching for misplaced tools or materials. These are forms of waste that slow down the process and increase costs, without delivering any additional value to the customer. For example, if an assembly line has to halt production because a machine is being repaired, the customer does not benefit from this delay, yet the cost of downtime is reflected in the final price.

- In service industries, NVA activities could include re-entering information into multiple systems, duplicating paperwork, or long wait times due to inefficient scheduling. These activities do not enhance the service the customer receives, and they often lead to frustration. For instance, if a customer has to wait in a long queue at a bank due to inefficient processes, this is a clear example of Non-Value Added time.

Importance of Classifying Activities

Understanding and properly classifying activities into these three categories is critical for organizations that aim to improve efficiency, reduce costs, and increase customer satisfaction. By identifying Value Added activities, companies can focus on optimizing and enhancing them, ensuring that they deliver maximum value to the customer.

For Necessary Non-Value Added activities, the goal should be to minimize their impact as much as possible. This could be achieved through automation, streamlining processes, or improving technology to reduce the time and resources spent on these tasks. For example, if quality inspections are necessary but take too long, companies might explore automated inspection systems that reduce time and human error.

Non-Value Added activities should be identified as waste, and the objective should be to eliminate them entirely from the process. Lean methodologies, such as Kaizen or Six Sigma, are often employed to systematically reduce or remove these activities. For instance, in a manufacturing plant, using visual management tools like Kanban can help minimize wasted time spent searching for materials.

By categorizing activities into these three groups, organizations can better understand where their resources are being used efficiently and where improvements are needed, leading to a leaner, more productive operation.

4 Steps to manage Value Added vs Non Value Added activities

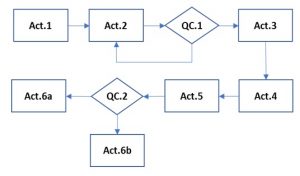

Step #1 – Mapping and Analyzing the AS-IS Process State

The initial phase in process optimization involves creating a simple process map or conducting a time study. This step is essential for capturing the current state of the process, known as the AS-IS state. Through this mapping, it becomes possible to visually identify and record all the activities involved in the process. This comprehensive identification is crucial for understanding the workflow and pinpointing areas for improvement. The process map or time study serves as a foundational tool for subsequent analysis and optimization efforts.

Value Added vs Non Value Added Mapping and Analyzing the AS-IS Process State

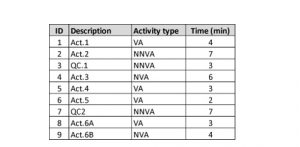

Step #2 – Value Added vs Non Value Added vs Necessary Non Value Added

The second step in the process improvement journey is the classification of all identified activities into three distinct categories:

- VA – Value Added: These are activities that directly add value to the product or service from the customer’s perspective. They are essential in transforming raw materials or basic inputs into the final product or service that the customer is willing to pay for.

- NNVA – Necessary Non Value Added: These activities do not directly add value to the product or service and are not something customers are willing to pay for. However, they are necessary for various reasons, such as compliance with regulations, maintaining process efficiency, or due to current technological limitations.

- NVA – Non Value Added: These activities do not add value to the product or service and are not necessary for the process. They are often considered pure waste and include tasks that only increase costs and time without contributing to the final value of the product or service.

This classification is pivotal for identifying areas where efficiency can be improved by either eliminating or optimizing specific activities.

Value Added vs Non Value Added vs Necessary Non Value Added

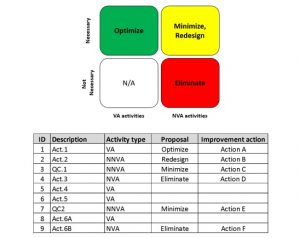

Step #3 – Implement improvement actions

Third step is to propose and implement improvement actions based on following matrix.

Implement improvement actions

One of the most common missteps in process improvement is the exclusive focus on eliminating Non Value Added (NVA) activities. However, it’s equally important to initiate actions aimed at minimizing Necessary Non Value Added (NNVA) activities and optimizing Value Added (VA) activities. Adopting a holistic approach that addresses all three categories of activities is crucial for the comprehensive optimization of the entire process.

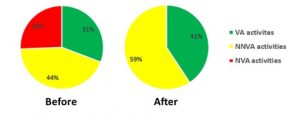

Step #4 – Present Before and After

The fourth step in the process improvement journey involves the calculation and visualization of the impact of the implemented action plan, essentially comparing the ‘Before’ and ‘After’ states. This stage is crucial for quantifying the effectiveness of the changes made.

Value Added vs Non Value Added – Before and After

By applying common sense and critical thinking, a significant amount of waste can be identified and eliminated, leading to substantial improvements in the process. This visualization not only provides tangible evidence of progress but also helps in identifying further areas for improvement, ensuring continuous process optimization. It’s a vital step for reinforcing the value of the changes made and for guiding future improvement initiatives.

Standardized Work in Eliminating NVA

Standardized work is an essential tool in distinguishing Non Value Added (NVA) activities from Value Added (VA) activities and plays a pivotal role in process analysis and improvement. Here’s how standardized work supports this critical analysis:

- Establishing a Baseline for Comparison: Standardized work creates a uniform baseline. This consistency makes it easier to identify deviations that may represent NVA activities, as they do not conform to the established standard (Standard Operating Procedure) of what adds value.

- Highlighting Inefficiencies and Waste: By defining the most efficient method to perform a task, standardized work helps in pinpointing areas where time or resources are being wasted. It allows for a clear visualization of the process flow, making it simpler to spot NVA activities such as unnecessary movements, delays, or redundancies.

- Facilitating Continuous Improvement: Once the process is standardized, it becomes easier to apply continuous improvement methodologies like Lean or Six Sigma. These methodologies thrive on clear, well-defined processes, and standardized work provides the necessary framework for systematically eliminating NVA and optimizing VA activities.

- Improving Process Understanding and Training: Standardized work helps in better training of employees (for example with the Training Within Industry program) by clearly defining what constitutes VA activities. This understanding is crucial for employees to identify and suggest improvements that can eliminate NVA activities, fostering a culture of continuous improvement.

- Enabling Better Measurement and Control: With standardized processes, it becomes feasible to measure performance against a known standard described in the SOP (Standard Operating Procedure). This measurement is critical in quantifying the amount of NVA activities and understanding their impact on the overall process efficiency.

Conclusions: Value Added vs Non Value Added

The distinction between Value Added (VA) and Non Value Added (NVA) activities is a fundamental aspect of process improvement. Understanding and categorizing activities into VA, Necessary Non Value Added (NNVA), and NVA is crucial for identifying areas of waste and potential enhancement in any operational process. The journey from mapping the AS-IS process, through classifying activities, to implementing and evaluating improvement plans, highlights the importance of a holistic approach.

Focusing solely on eliminating NVA activities is not sufficient; optimizing VA activities and minimizing NNVA activities are equally important. This comprehensive strategy ensures not just the elimination of inefficiencies but also the enhancement of the overall value delivered to the customer. The practice of continuously analyzing and improving these elements can lead to significant enhancements in efficiency, cost-effectiveness, and customer satisfaction. In essence, the balance and interplay between Value Added and Non Value Added activities form the cornerstone of effective process optimization and organizational excellence.

Nenad Marcetic is CIO at Lean Community. He has over 15 years of experience in Lean Management. He is a graduate of Quality Management. He has conducted more than 250 management system audits in various companies and industries (manufacturing, food and beverage, agriculture, IT services, finance, retail, mining). Since 2015 in a global automotive company, where he is responsible for process standardization and the implementation of the IATF standard.