As I agreed, I will be talking about the 14 Toyota management principles described by Jeffrey K. Liker in the book: The Toyota Way.

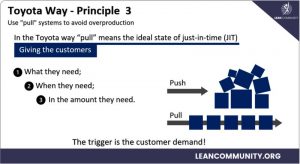

Principle 3 – Use pull systems to avoid overproduction

The pull system produces only the required material after the subsequent operation signals a need for it. This helps to avoid overproduction and overordering.

The goal of a pull system is to maintain small quantities of inventory that you know are needed, and replenish only when it has been taken. In the Toyota way “pull” means the ideal state of just-in-time (JIT) manufacturing, giving the customers what they need, when they need, in the amount they need.

Base on this affirmation we can assume that the trigger to start the whole process is the customer demand.

This approach will drastically reduce the waste of overproduction, one of the biggest tenets of the Toyota Production System. It can save companies a lot of money!

Toyota Way – Prinicple #3. In today’s fast-paced business environment, organizations are constantly seeking ways to optimize their operations, minimize waste, and deliver value to customers efficiently. One such approach that has gained significant traction is the pull system. In this article, we will delve into the concept of the pull system, its benefits, and its alignment with the renowned Toyota Production System. By embracing the pull system, organizations can reduce overproduction, optimize inventory levels, and save substantial costs.

Understanding the Pull System:

At its core, the pull system operates on the principle of producing materials or goods only when there is a signal or demand from the subsequent operation. Instead of pushing materials through the production process based on forecasts or arbitrary schedules, the pull system ensures that production is triggered by actual customer demand. This approach eliminates overproduction and the associated waste.

Just-in-Time (JIT) Manufacturing:

The pull system is closely linked to the concept of just-in-time (JIT) manufacturing, a key component of the Toyota Production System. JIT aims to provide customers with the right quantity of products they need, precisely when they need them. By aligning production with customer demand, organizations can achieve optimal inventory levels, reduce lead times, and enhance customer satisfaction.

Customer Demand as the Trigger:

In a pull system, customer demand acts as the trigger to initiate the production process. Rather than relying on forecasts or assumptions, organizations focus on understanding and responding to actual customer needs. This customer-centric approach ensures that resources are allocated efficiently, and production is aligned with real-time market demand.

Waste Reduction and Cost Savings:

Toyota Way – Prinicple #3. By implementing a pull system, organizations can significantly reduce waste, particularly the waste of overproduction. Overproduction ties up valuable resources, including materials, labor, and storage space, without adding value to the end customer. By producing only what is needed based on customer demand, organizations can streamline their operations, reduce excess inventory, and realize substantial cost savings.

See the column about the Prinicple #12

Mechanical Engineer with the emphasis on manufacturing industry, highly organized, with good communication and project management skills. Always focused on reducing costs, and delivering results by using the resources I've learned in my studies, along with the experience gained from the companies I worked. Key strengths: Project Management, TWI - Training Within Industry, Lean Manufacturing, Process Standardization, Leadership of multi-functional teams, Strategic Planning, Continuous Improvement, Extrusion Tooling Design, Extrusion Process, CAE Analysis.