Lean and Agile – similarities. At the last Lean Trends conference, one of the thematic blocks was devoted to Lean Agile. Although at first glance this combination seems exotic (Production, IT, who has seen it?), their DNA is similar. It is interesting how experts in various industries come to similar conclusions when it is development that is the overriding value, and not the defending of the status quo. You can also hear skeptical voices that similar treatments were meant to only sell old trainings in their new version (first association – Prince 2 Agile). Let me assure you that in this case they are greatly exaggerated.

In fact, combining Lean and Agile is natural. In the Scrum manual (by Ken Schwaber and Jeff Sutherland), we can read in the front pages that Scrum is based on empiricism and the concept of Lean. Every experienced Lean expert, even if they have not had any experience with Agile, will find familiar values in the Agile Manifesto. As an interesting fact I can add that Toyota recruits Agile Coaches to its ranks. In turn, the IT industry is willing to pay a lot of money for experienced Lean experts. The largest players noticed the advantages of the synergy of both approaches a long time ago. Therefore, let’s check in which areas Agile and Lean coincide.

Table of Contents

ToggleGenesis

Before talking about the key similarities, it is worth mentioning the story of the origin of both approaches. It’s interesting how Lean and Agile have evolved to the form we know today. There are already a number of common points in their genesis, such as the overriding role of the exchange of knowledge between Japan and the USA, or the strong separation from previous methods of work.

Lean

Lean is a concept, the origins of which can be traced back to the Toyota Production System. The Toyota company created its system after being inspired by the method of car production in Henry Ford factories. Both the history of Ford and Toyota have been described many times in literature. However, I want to highlight a fundamental point. After World War II, for a long time, the only form of reducing production costs were the so-called economies of scale. In practice, this meant that the focus was on producing as many products in a linear manner as possible. If achievable, the processes were automated. I will quote the words of Bill Gates, which are a bit worn-out as they are overused, but they are very accurate: “The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency. The second is that automation applied to an ineffective operation will magnify the inefficiency”.

Toyoda faced market limitations, i.e. a relatively small Japanese market (when compared to the US) and a limited supply of raw materials. These factors and the need to produce in small batches were the foundation of what the West called in the 1990s “lean production”. It involved eliminating waste (muda) and shortening the order fulfillment time as much as possible. Consequently, quality was improved and costs were reduced. The Lean concept began to extend beyond production. Lean Office, Lean in IT, Lean in transport. Toyota pursued a policy of transparency and allowed their tools and methods of work to be copied. These copies were not always successful. This was due to Toyota’s unique organizational culture, which is impossible for Western companies to imitate.

Agile

We can consider 2001 as the official date of birth of Agile philosophy. It was then that the Agile Manifesto was created, i.e. a unique declaration of principles and values. However, the spark that set Agile in motion flared up much earlier. In 1986, two Japanese professors published an article entitled “The New Product Development Game.” Hirotaka Takeuchi and Ikujiro Nonaka, because we are talking about them here, have shown how ineffective the traditional approach to project management is. The waterfall (or cascade) approach, which has been promoted by NASA, was a generally accepted standard for project management. However, the largest organizations such as 3M and Honda used a different model. The authors analyzed the work style of the most effective players on the market. They showed that advantages are built by establishing autonomous teams, and not by centralizing decisions. Managers, in turn, were not herdsmen, but they played the role of a servant and paved the way for their teams to work freely. An interesting comparison was used in the article – the work of the best project teams was compared to the cooperation of rugby players in a scrum.

After 7 years, the article was handed over to the author of the Scrum methodology – Jeff Sutherland. He was looking for an alternative to the waterfall model, which is ineffective in the programming environment. Despite the fact that “The New Product Development Game” considered production, J. Sutherland still found what he was looking for in it. Two years later, he and his colleague Kenn Schwaber described what the new way of building software is. They presented their assumptions at the Association for Computing Machinery conference, under the name “SCRUM Development Process”.

Lean and Agile similarities

- Correctly understood efficiency

Efficiency is key when it comes to Lean and Agile, and is also their common denominator. Lean and TPS have process efficiency coded in their DNA. Lysa Addkins devoted a whole chapter to this topic in her great book “Coaching Agile Teams”. Efficiency should be expected from both processes and self-organizing teams.

In the case of Agile, efficiency should not be confused with business results. The latter are achieved through standard procedures and by responding to the client’s demands (at least in theory). In the reel of sprints and retrospectives, it is easy to fall into a routine and feel like the main character of the movie “Groundhog Day”. Therefore, more is needed. It is Continuous Improvement. Sounds familiar?

I observe the same approach in Toyota – the home of TPS (Toyota Production System). Operational efficiency is not everything, and therefore innovation and continuous improvement are also key. In the traditional, ineffective approach, the so-called “Local factors of efficiency” are being searched for (J. K. Likker). These are, for example, additional machines, accelerating cycle times or, interestingly, non-reflective automation and the replacing of human work with machines. The result of such action is the improvement of a certain process, but it does not benefit the overall value. This is because a significant proportion of processes involve activities that do not add value to the final product. Lean recommends improving activities that add value to the product and reducing activities that do not add value.

- Proactive approach to problems

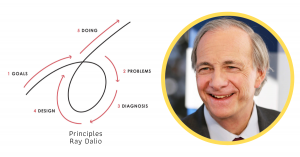

A proactive approach to emerging problems is a common feature of Lean and Agile. Both concepts are based on the assumption that problems are a great opportunity to develop and improve processes. That is why a lot of tools have been created that are applicable when we operate in these environments. The real obstacle is camouflaging the problem. As an interesting fact I will add that the standardized Problem Solving process was also introduced by Ray Dalio, the owner of the largest hedge fund in the world. You can read more about this in his great book “The Rules”.

There is an entire process in Agile that is devoted to reflection and the analysis of made mistakes. We are talking here about the retrospective. After the sprint is over, we start the retrospective. And the retrospective itself starts with the so-called Problem Zone. This is the stage during which problems are identified, accurately described, and attempted to be understood. Then it goes to brainstorming. The purpose of this stage is collecting information and opinions on the previous stage of work. The most important thing in this step is collecting uncensored information, and it is therefore necessary to appropriately conduct this process in a way that all participants feel safe. The third stage is dot voting, when ideas and potential improvement have already emerged, and they should be grouped and analyzed. Importantly, the team decides which problems they want to solve and how. There is no place here for top-down and directive decisions. This is at odds with Agile’s assumptions about self-organizing teams.

Taiichi Ohno once said that a production line that doesn’t stop is either excellent or extremely bad. Perfection, of course, is impossible. The context referred to the situation when the production line stops working and everyone is trying to solve the problem. Everyone is involved in looking for a good solution. This is the reason why you should build a system where, first of all, every problem is immediately visible. When they are imperceptible, there is no way of effectively managing the process. Secondly, everyone must be involved in troubleshooting. The essence is collective action. There is no place for hiding problems or solving them post factum in conference rooms. In a nutshell, a proactive approach to problems is to build an organization where problems are made visible. A goal is then set that is clear and understandable by all. The goal is compared with the obtained result on an on-going basis. Deviations are treated as a problem to be solved – this is

also a standardized process. The last stage is Kaizen, i.e. introducing an improvement. The target situation assumes that after the implemented improvement, the problem does not return.

- Focus on the customer

Focus on customers is the common denominator of both approaches. Their requirements usually change over time, and therefore iterative product development is effective. This way of working was something refreshing and innovative when compared to traditional waterfall methods of managing projects. In order to introduce a new style of work, it was necessary to show a lot of flexibility, which is missing in other methodologies, such as e.g. Prince 2. As an interesting fact I would like to add that the studio producing computer games – Blizzard – when creating the hit Diablo 2, was the first to break with the traditional waterfall approach to product development. The voice of the client was listened to and the individual elements were added iteratively. Due to this, time was taken to grind the components that represented actual added value for a customer. The results exceeded the expectations of the creators. Diablo 2, as one of only a few games, is constantly gaining interest. Despite its advanced age (released in June 2000) it has active servers and countless players.

The customer’s voice is the foundation of Lean. If we follow the principles of the Toyota Production System, we will notice that the customer’s perspective is emphasized at every stage. Lean companies analyze their processes and focus on those elements “for which the customer wants to pay” – the ones that add value to the product. For organizations that have not used a similar approach before, it may seem controversial. Quality control activities are a good example of this. Too often this is only a safeguard for the manufacturer so that a defective product does not enter the market. Customers want to buy a product that meets their requirements. However, they do not want to pay for unnecessary quality control.

It is worth quoting the words of Art Byrne at this point: “An organization is a group of people, a set of processes and a unit that delivers value to a specific set of customers”. This statement is valid when we look at a company through the prism of Lean and Agile.

- Defining the role of the leader

Both the Lean concept and the Agile methodology characterize the role of the leader in a very interesting way. Something that we are learning today was quite a novelty in the 90s and earlier. The subject of leadership and management is so extensive that you can write books about it. Anyway, this also happens because the shelves in bookstores are bending under the weight of items regarding this topic. The leader is an integral part of the team. Unlike colloquially called managers, he is not above the team. He does not behave in a directive manner that does not accept opposition. It is a person who, thanks to their skills and position in the organization’s structure, paves the way and removes obstacles for the team’s goal. Therefore soft skills are so important in the leader’s work. Coaching, facilitation or moderation of the course of meetings are part of the daily work of the leader.

There are, however, situations when the role of the leader is perceived incorrectly. Being a leader does not mean having a passive or protective approach to situations that arise in the team. Even if teams are autonomous or self-organizing, there is a need for them to function within specific frameworks and structures. Nobel laureate – Ilya Prigogine – discovered that systems can only organize themselves within a certain framework. Interestingly, the same applies to AI – decades passed before it was discovered that AI can only function within certain structures, frameworks, and limitations. Teams are no different in this respect. Therefore, the leader is a person who builds this structure.

It is also worth noting that Leaders are subject to the same rules as teams, and they need the framework in which they function. This means that in order to be effective, they need behavioral patterns and guidelines. The values of the organization and its missions are necessary. I am talking about this because too often leadership is viewed as a random and undefined set of Leaders, and not as a value that flows directly from the organisation’s DNA.

- Employee development

There is a kind of meme circulating on the Internet – “Why should we develop people if they leave us anyway? – Think then what will happen if they stay with us.” This funny dialogue draws our attention to the need of investing in the development of employees’ competences. Carol Dweck in her book “The New Psychology of Success” described the value of practical learning and continuous self-improvement. What’s more, she poses this as a major indicator of success.

The days when workers were treated with tools are gone. Today they are specialists in theirs areas and are focused on development and expanding their knowledge. When delving into Lean or Agile, you can easily see how big a role is assigned to people at every organizational level. This is why the key is to build a work environment that fosters their growth. They are the closest to the process and very often have ideas on how to improve it. Therefore, so much emphasis is placed on skills that enable the full potential of all working people to be activated in the organization – not only those who, at least in theory, are responsible for thinking.

The organization should shape the development of employees on several levels, with one of them being expanding competences. For example, Skill Matrix is used for this purpose. The key is to set ambitious goals together in order to ensure appropriate conditions and means to achieve them. However, you should refrain from over-controlling. Let the workers spread their wings. I consider the beginnings of the Lexus brand to be an ideal example of such a move. Ichiro Suzuki, Toyota’s chief engineer, was appointed to be responsible for building the first Lexus model and conquering the premium car segment. The story is amazing and I sincerely recommend everyone to get to know it. You will find it in the book “The Toyota Way” by Jeffrey K. Liker. The third area is engaging employees, listening to their voice, and implementing their ideas – allowing and enabling employees to improve their positions and processes. Allowing for them to influence the development of organizational culture. Finally, I would like to add that in the top 10 of the most important expectations for leaders (Openfield 2021) are “Providing space for mistakes and learning” and “Involvement in employee development”.

Summary

I hope that the topic of similarities between Lean and Agile has become more familiar to you. However, remember that there are several areas where both approaches are mutually exclusive. I wanted to show my subjective perspective and help people who connect these two areas or need a connecting point when moving from one industry to another. What I want to sensitize is the use of proven sources of knowledge about Lean and Agile (although this applies to every phenomenon).

One of the similarities that is also worth writing about is that it’s also a business – that’s why if we use the help of external consultants, let’s do good research. The right person will help us avoid mistakes, and this person will be a turbo-charging and invaluable help. A bad choice of help will result in making mistakes that are likely to bring down the transformation and discourage employees from changing.

Finally, I would like to add that Lean and Agile reveal the problems that are faced by organizations. Any change, even ones for the better, causes an increase in stress, a disruption in safety, and a blockage among employees.

We should remember this when acting as a change agent.

Contact the Author: https://spacerpoleanie.pl/

References

- L. Adkins, Coaching for Agile Teams.

- J. Appelo, Management 3.0. Managing teams using Agile methodologies.

- A. J. Blikle, The Doctrine of Quality. The thing about turquoise self-organization.

- R. Drzewiecki, Lean Strategy.

- M. Cohn, Agile. Agile methodologies in project planning.

- M. Imai, Gemba Kaizen.

- J. K. Liker, The Toyota Way. 14 management principles of the world’s leading manufacturing company.

- A. Byrne, How to Implement Lean. A practical guide.

- C. Dweck, The New Psychology of Success

My name is David. I believe that changing the culture of an organization can be simple, and my goal is to provide information and ways to make this possible. I am responsible for the development of teams in 10 locations. I adhere to the principle of "people first, tools later", and that partnership and trust is the key to building the company's value.