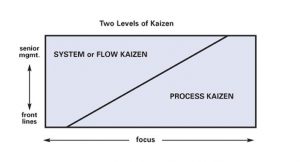

Kaizen – let`s play the game! Kaizen is a Japanese term for continuous improvement. It is literally translated as: “change for better”. In the business practice this approach is connected with some fundamental principles, such as: team work, orientation towards elimination of a source of a problem, using of facts and data, or engagement of every worker. One distinguishes two kaizen approaches:

- flow kaizen;

- process kaizen.

The former is oriented towards flow of materials and information, and often identified with the reorganization of an entire production area, even a company. Whereas, the latter means improvement of individual workstands. Therefore, the improvement of ways production workers do their job is a part of process kaizen. However, the kaizen model combines both approaches with process kaizen – concentration of workers on continuous small improvements – as the prominent element, contrary to the traditional model based on larger reorganization projects. In the latter case the time between the concept development and the project implementation is very long. In the kaizen model one seeks mostly for small ideas which can be implemented on the same day preferably.

Fig. Kaizen Flow vs Kaizen Process (Source)

In the traditional model one forms project groups and devotes much time to analysis. It also requires the involvement of several departments in a project, such as H&S, finance, quality, etc. The realization of reorganization applications is way better than the lack of improvement initiatives. For sure! However, the problem is that time and costs limit the maximum number of reorganization actions to a few per year. There are situations when a complete pre-implementation analysis is taken, and a reorganization project is dropped due to e.g., changes in a budget. Small improvements, as a part of the kaizen model, are characterized by the fact that they are resistant to such aspects. Mostly, due to their short implementation period. As a matter of fact, there can be thousands of such improvements! So, the advantage of kaizen over the traditional model is economies of scale. The most important aspect of kaizen is to shorten the time between the concept development or problem definition and the improvement implementation. Moreover, kaizen is not limited to small improvements. Check out fig 3.1. once more. Higher elements symbolize large, flow kaizen improvement projects. However, small, process kaizen improvements prevail. The kaizen model is about one simple rule: a small improvement today is better than a large improvement tomorrow. But the gate to flow kaizen ideas is open.

Advantages of kaizen over the traditional model

Let me present you the advantages of kaizen over the traditional model by means of a certain money game. You can also use it to prove the benefits of small improvements and convince others to kaizen.

The game

I’d like to give you money for the next 31 days. I’ve got two proposals. The first is that I’ll give you a fixed amount of money – 1000 $ – every day for the next 31 days. The second is that every day for the next 31 days you’ll receive the amount twice as higher as the amount given on the previous day. I’ll start with 1$. Both proposals are presented in table 1. You have a few seconds to choose one of them.

Tab.1. Cycle no. 1

| Proposal no. 1 | Proposal no. 2 | ||

| Day no. | Amount given | Day no. | Amount given |

| 1 | 1000 $ | 1 | 1 $ |

| 2 | 1000 $ | 2 | 2 $ |

| 3 | 1000 $ | 3 | 4 $ |

| …. | … | … | … |

| 31 | 1 000 $ | 31 | ? |

| TOTAL | 31 000 $ | TOTAL | ? |

You’ll not likely to count the amount you can gain in the second proposal. If you like gambling, you’ll choose the second option. My experiences, however, show that over 80% opt for proposal no. 1. They simply don’t know what to expect from the proposal no. 2. Their intuition tells them that they won’t get much. All in all, it’s just 31 days.

If you’ve chosen the second proposal, let me just change the rules. Proposal no. 1 stays the same, whereas proposal no. 2 starts from 0.1 $ instead of 1 $ (table 2.). So, which one will you choose?

Tab. 2. Cycle no. 2

| Proposal no. 1 | Proposal no. 2 | ||

| Day no. | Amount given | Day no. | Amount given |

| 1 | 1000 $ | 1 | 0.1 $ |

| 2 | 1000 $ | 2 | 0.2 $ |

| 3 | 1000 $ | 3 | 0.4 $ |

| …. | … | … | … |

| 31 | 1 000 $ | 31 | ? |

| TOTAL | 31 000 $ | TOTAL | ? |

Kaizen – let`s play the game! You know perfectly well that it’s just 31 days. You probably have chosen the first proposal. Don’t you worry; over 99% will do the same. But if you stick to the second proposal, there’s going to be another change in the rules. No changes in proposal no. 1, but this time proposal no. 2 starts from 0.01 $ (table 3). Choose wisely.

Tab. 3. Cycle no. 3

| Proposal no. 1 | Proposal no. 2 | ||

| Day no. | Amount given | Day no. | Amount given |

| 1 | 1000 $ | 1 | 0.01 $ |

| 2 | 1000 $ | 2 | 0.02 $ |

| 3 | 1000 $ | 3 | 0.04 $ |

| …. | … | … | … |

| 31 | 1 000 $ | 31 | ? |

| TOTAL | 31 000 $ | TOTAL | ? |

Kaizen – let`s play the game! It’s highly probable that you have no doubts – you claim that the first proposal is the best. You are still aware that it’s only about 31 days. However, let me say that by choosing proposal no. 2 starting from 0.01 $ you would get 21 474 836,48 $ after 31 days. I’m not joking! The amount in the second proposal would exceed 31 000 $ on the 22nd day! I know, it’s amazing. That’s the magic of small ideas. This is how kaizen works. It’s the economies of scale.

Dr. Bartosz Misiurek is a co-founder of a few start-ups like Leantrix, Lean Community, Leancoin, etwi, Lean Global Consulting, Sallar. He is a CEO at LeanTrix Ltd., Leancoin Ltd, Do Lean IT OU, and a Member of the Board at Astral Hodling OU. Author of the book “Standardized Work with TWI: Eliminating Human Errors in Production and Service Processes.” He works as Sr Manager and TWI Global Coach at Automotive Company.