Table of Contents

ToggleIntroduction

We all have seen that in some specific business, checklist are widely used even for repetitive jobs, no matter how many times the worker performed a specific task or if this is the 4th time that day he or she is repeating the job. But all this appear normal to us, in some conditions. Let’s take a look at aviation checklists: pilots are probably the most trained category of all human industry, but nevertheless they have to go through all those checklist they probably could repeat by memory many times per day… Why?

Think about the final purpose of a checklist:

the need to perform a list of tasks we have to be 100% they are completed, and to reduce to the minimum the human error. In the case of aviation industry, the time consumed to go through a checklist is worth comparing to the level of safety needed, and this is probably the reason why nobody is complaining about this time-consuming method.

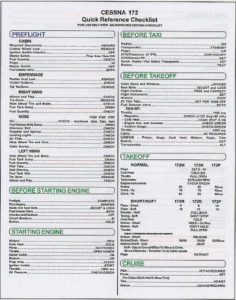

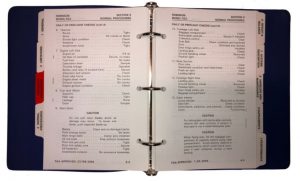

(images from website https://pilotteacher.com/)

In fact, first pre-flight checklist were developed in 1935 after plane crash due to a human error.

Later on, 4 standard were defined: takeoff, flight, before landing, and after landing, with the gaol of reducing the possibility oh a pilot to make a mistake or forget key points in the critical phases of the flight. Today, the safety of aircrafts is at highest level ever, and human mistakes are rarely the cause of an accident (and in some cases, the cause was a skipped task of a checklist!)

Why we probably need a checklist

Checklist Completed! The usage of “to-do list” are now spread in different businesses, and there are few different reasons, and probably only one root cause: a human brain has a slot for short-term memory up to 9 items (in average, it’s generally accepted a range between 7 to 11). It could seems enough for managing temporary task such as those we are doing at work, BUT this memory is highly volatile, is affected by distractions, by time, how much we are tired, and other external input our brain is receiving. In the cases we need to be absolutely sure that some tasks are completed (such as performing a sequence of actions before the takeoff of an airplane), follow checklist with 100% discipline is the only way to get out safely and effectively.

What kind of checklist?

In aviation, there are generally two kind of list: a “Do-Confirm” and “Read-Do” checklist.

Read-Do

A “Read-Do” is somehow similar to follow a recipe during cooking process: you just simply have to read what to do, and perform the task! But this method can be useful as well for troubleshooting; in fact, this kind of document is a perfect way to collect and standardize a certain level of knowledge. Imagine a team that already had s similar problem in the past, and that probably already found a way to solve or at least to contain the potential negative effects.. well, what is the best way to be sure that someone will replicate smoothly the steps to get out of a similar problem? The answer could easily be a “Read-Do” checklist!

Do-Confirm

This is the most familiar checklist for all of us: it simply consist in a list of things or items to check, to be sure they will be performed or completed. This method is widely used to assure we are in a certain condition before we are proceeding to a next step of phase of our process. But, as many other methodologies, it has a weak point: the human that has to go through all points, without skipping a single item. Unfortunately, humans are the main cause of failures, as we all have tendency to be lazy and to take shortcuts, that is exactly what this methods should help us to avoid. When is the right moment to implement them. So, should we start using checklist everywhere, every time? Absolutely not. What can drive us in deciding when using checklists could provide a real benefit for our jobs? Let’s try to find out.

- Safety could be improved, thus benefit are not in discussion

- Benefits should be higher than time consumed to go through the list

- Troubleshooting, for repetitive or basic problem before escalation

Category Reason Example Safety Assuring a mandatory task or condition is accomplished Turning off a machine before a maintenance activity, assuring nobody could restart it Cost/Benefits A mistake could lead to bigger cost comparing to the time spent to go through it A complex process or machine that, once is started, is difficult or expansive to stop Troubleshooting A list of questions or things to control that are coming from lessons learned Problems already solved in the past, that can happen again and can be easily stopped checking the corrects key elements

These above are just few examples about benefits we could gain when trying to keep under controls the key elements that are constraints in our organization. But while checklist and control documents are widely used in the first two categories, we cannot say the same about the “troubleshooting” category: in this case, a document helping our employees to take the right decision is fundamental but rarely used. We tend to refer to our memory or to expert employees, while rarely trying to collect this experience in a document; in this case, a good checklist could be like a book of knowledge gathering all our experience and things we learned from our past mistakes.

The “good” checklist!

There are plenty of examples of control list; some with simply check boxes, others with huge list of things to do, and some even with text box where to write comments, or ticking the “yes” or “no” text box (but we are not just checking for the evidence of the paper job, right?). These kind of documents are usually the ones that nobody will follow: the tick-box takes time and makes no sense to be used while the task is performed, or there are too many items on the list. So why checklist are failing?

- just a check-box (lazy humans will try the way to find shortcut or to fake it!)

- too many items or task

- high complexity / not structured

So what we can do to make them more effective?

- Use them only when we could really get a benefit (see table above)

- Only add key elements

- Use minimum amount of words

- Write task and actions using also “visual” info (e.g. FUEL switch -> CUT OFF/LEFT POSITION)

- Highlight most important task or info (a choice, a message you could get on machine, a key element

In aviation documents we can usually find:

- Task on the left

- Action or condition on the right (action to execute to complete the task or condition to confim)

- Throttle lever……..Idle

- FUEL Switch……..CUT OFF/LEFT

- Doors……………..Unlocked

- Parking brakes…..Activated

In this case, pilots (and all human brains) can easily manage a series of task with just few words, and the way we write the message could help to visualise in our mind the action or the condition we need to achieve.

Some additional examples from our daily business:

- Lockout/Tagout checklist

- Supervisor..……….Informed

- Workers……………Informed

- Machine……………OFF

- Electrical Switch….OFF

- Switch Lock………LOCKED

- Tag………………….in place

- PPE…………….…..on

What is usually defined in safety procedure can be summarised and quickly performed in this way, following the given rules about using few clear words, highlighting the key task and actions. Our brains can easily deal with such structured sequence of information, and it will be easier for the operator to follow all points if they are as clear and simple as described.

And now imagine how a troubleshooting control list could look like:

- Material………………….compliant

- Work Procedure………..followed

- Temperature set………..250 °C

- Oil pressure…………….GREEN area

- Mould surface………….clean

- Similar machine………..check –

IF similar machine show no problem - Supervisor……………..inform

- Production……………..stop

- Box……………………..substitute

This sequence recall what could be common problems already solved in the past (oil, temperature and cleaning), support in remembering which key elements we need to keep under control (material and process settings) and give the operator an hint about checking status of similar machine in case they are facing same problem with same material. We could call this a first level of analysis, where workers could easily start the problem solving process on their own, and maybe even defining and solving it, before going to the escalation. Even in this case, the supervisors could avoid checking again the basics items and stating the second level of investigation with technical and engineering team.

Closing Remarks

Checklist Completed! In this short overview, I tried to summarise the why, when and how we could gain benefits of using checklists in our everyday work tasks. But please remember that the checklist is not a substitute of a training or a procedure: in all example above, it should be clear that activities are performed by workers that were trained and qualified to perform the job. A control list will be just the tool to support workers in being more effective, standardising decision processes and reducing risk of human mistakes given by time pressure, emergency or overconfidence. Never give checklist to people that is not aware about the job they have to perform!

And now, after finishing reading, we could surely say: checklist completed!

References:

How PILOT CHECKLISTS increase your PRODUCTIVITY? | Captain Joe

https://www.youtube.com/watch?v=iUD55KscxsA

The Magical Number Seven

https://en.wikipedia.org/wiki/The_Magical_Number_Seven,_Plus_or_Minus_Two

Andrea Manti is CBDO at Lean Community. He has over 15 years of experience in Lean Management. He is an expert in Lean and Quality Management and has held positions working as a Process Engineer, Customer Quality representative, Quality System Manager (IATF standard), and Continuous Improvement Senior Manager. During his career, Andrea has led the implementation of several Lean/6Sigma projects, TPM workshops, and TWI activities. He is also an expert in the World Class Manufacturing (WCM) program