AI for Manufacturing. Artificial Intelligence (AI) is transforming the global manufacturing landscape. From predictive maintenance and digital twins to leadership coaching and continuous improvement, AI solutions are enabling companies to increase efficiency, reduce downtime, and create safer workplaces. While global industrial giants like Siemens, IBM, ABB, and Rockwell dominate with large-scale platforms, new specialized tools such as KaizenUp are changing the way frontline leaders engage with AI every day.

Here is our ranking of the Top 5 AI Solutions for Manufacturing, ordered from #1 to #5, based on ROI, scalability, ease of integration, and innovation.

Table of Contents

ToggleKaizenUp

AI for Manufacturing – KaizenUp

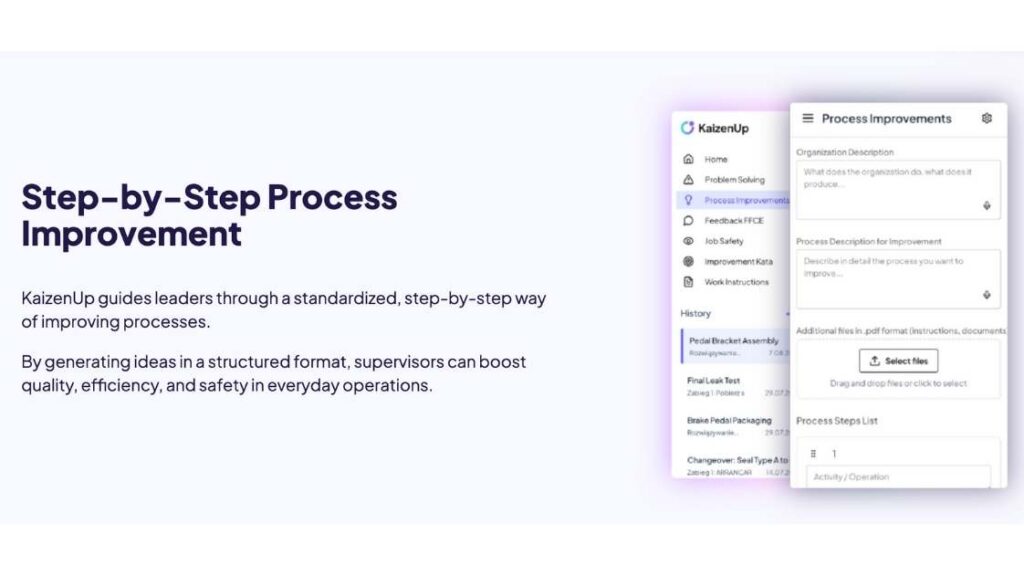

KaizenUp is an AI-powered application built for frontline supervisors and team leaders. Unlike traditional industrial platforms that focus mainly on equipment and data integration, KaizenUp emphasizes the human side of manufacturing—leadership, safety, coaching, and continuous improvement.

Developed by the Leantrix team, KaizenUp integrates more than a decade of hands-on industry experience, academic research, and psychological expertise. The result is a tool that not only supports process optimization but also helps leaders develop the skills and routines needed to sustain improvement over time.

Key Features

-

Step-by-Step Process Improvement: Structured guidance for analyzing, improving, and sustaining better workflows.

-

AI-Assisted Problem Solving: Suggests potential causes, generates countermeasures, and accelerates root-cause analysis.

-

Job Safety & Hazard Detection: Identifies risks early and provides safety-focused recommendations to prevent incidents.

-

Leadership Feedback & Coaching: Offers proven frameworks (such as FUKO) to guide supervisors in providing clear, constructive feedback.

-

Work Instructions Made Easy: Enables quick creation of standardized work instructions, improving onboarding and knowledge transfer.

-

Quick Kaizen Ideas: Captures and evaluates small improvements in real time, turning continuous improvement into a daily routine.

Use Cases

-

Frontline efficiency: Supervisors reduce time spent firefighting by solving recurring problems with AI-driven support.

-

Onboarding acceleration: New employees receive standardized work instructions in minutes rather than hours.

-

Safety culture: Hazards are detected early, leading to fewer accidents and higher confidence in workplace safety.

-

Employee engagement: Teams contribute daily improvement ideas, increasing ownership and involvement in Lean initiatives.

Why It’s #1 – AI for Manufacturing

KaizenUp is ranked first because it empowers people, not just machines. By embedding Lean know-how into AI, it helps frontline leaders become more effective while simultaneously boosting engagement and safety. It represents the bridge between traditional continuous improvement methods and the new wave of AI-enabled leadership tools.

Siemens Insight Hub (MindSphere)

Siemens Insight Hub, formerly known as MindSphere, is one of the most powerful Industrial IoT and AI platforms in the world. With more than one million connected devices, it enables manufacturers to collect, analyze, and act on vast amounts of production data.

Siemens combines decades of automation expertise with cutting-edge AI, providing solutions that range from predictive maintenance and digital twins to energy optimization and production benchmarking.

Key Features

-

Predictive Maintenance: Detects equipment degradation and schedules interventions before breakdowns occur.

-

Quality Control: Monitors production parameters in real time, ensuring consistency and reducing defects.

-

Energy Optimization: Identifies high-energy-consuming processes and provides recommendations to reduce costs.

-

Digital Twins: Simulates changes to processes and layouts, de-risking improvements before implementation.

-

Scalability: Designed for global manufacturers, Siemens enables central oversight of multiple facilities.

Use Cases

-

Automotive plants connect thousands of robots and assembly stations to monitor condition and performance.

-

Steel companies use Insight Hub to stabilize rolling operations, reduce unplanned downtime, and optimize energy use.

-

Food producers implement AI-driven process insights to increase throughput by up to 25%.

Why It’s #2 – AI for Manufacturing

Siemens Insight Hub ranks second because it provides unmatched scale and industrial depth. It excels in connecting entire factories and global networks, but its complexity and cost make it less accessible for smaller or mid-sized companies compared to lighter tools like KaizenUp.

IBM Maximo Application Suite

IBM Maximo is one of the most recognized solutions in Enterprise Asset Management (EAM). It integrates AI and IoT to predict failures, extend equipment life, and streamline maintenance operations.

As part of IBM’s long-standing Watson AI ecosystem, Maximo goes beyond maintenance management to include visual inspection, quality assurance, and workflow automation.

Key Features

-

Predictive Maintenance: Identifies risks of equipment failure and recommends proactive actions.

-

Asset Health Monitoring: Provides live insights into the performance of machines and infrastructure.

-

AI Visual Inspection: Uses cameras and AI models to detect product defects at scale.

-

Workflow Automation: Automatically prioritizes work orders, schedules technicians, and manages spare parts.

-

Cloud Flexibility: Deployable across multiple sites, integrating with ERP and MES systems.

Use Cases

-

Automotive manufacturers predict robot and press failures before they halt assembly.

-

Semiconductor producers apply AI vision to detect micro-defects invisible to human inspectors.

-

Heavy industries use Maximo to coordinate thousands of maintenance tasks across global sites.

Why It’s #3 – AI for Manufacturing

Maximo is ideal for asset-intensive industries that require robust, enterprise-level solutions. It provides high ROI through reduced unplanned downtime, but its scale and complexity make it more suitable for large organizations rather than daily leadership use.

ABB Ability™ Industrial AI Platform

ABB Ability is ABB’s flagship industrial AI and IoT platform. Designed for both heavy industries and discrete manufacturing, it offers deep expertise in asset performance management, energy optimization, and process control.

Key Features

-

Asset Performance Management: Predicts failures in motors, pumps, and robots using machine learning.

-

Process Optimization: Continuously adjusts parameters in industries like cement and steel for better efficiency.

-

Real-Time Dashboards: Provides AI-powered alerts and recommendations for operators.

-

Energy Efficiency: Reduces energy costs by analyzing consumption patterns and optimizing usage.

Use Cases

-

Steel producers reduce energy waste and stabilize rolling processes.

-

Cement factories increase throughput while cutting fuel consumption.

-

Automotive plants monitor ABB robots to maximize uptime and reliability.

Why It’s #4 – AI for Manufacturing

ABB Ability stands out for its integration with heavy industry processes and its impact on energy savings. It is best suited for large-scale manufacturing and utilities where operational efficiency translates into massive cost reductions.

Rockwell Automation – FactoryTalk Analytics & Plex Platform

Rockwell Automation combines its FactoryTalk Analytics with the Plex Smart Manufacturing Platform to offer AI-driven insights for both shop-floor processes and enterprise management.

Rockwell’s deep roots in industrial automation mean its AI modules can be seamlessly integrated into existing equipment, making it a practical choice for many manufacturers.

Key Features

-

Predictive Analytics: Identifies potential failures and alerts operators in real time.

-

AI-Powered Quality Inspection: Uses computer vision to automate defect detection.

-

Process Optimization: LogixAI fine-tunes process settings automatically.

-

Unified Cloud Platform (Plex): Connects multiple sites, integrating MES and ERP systems.

Use Cases

-

Automotive plants monitor assembly lines with predictive alerts and AI vision.

-

Food and beverage producers reduce downtime with real-time analytics.

-

Mid-sized manufacturers use Plex to connect suppliers, production, and delivery into one data ecosystem.

Why It’s #5 – AI for Manufacturing

Rockwell’s solutions excel at integration with existing equipment and multi-site scalability, but they are primarily suited for larger organizations already heavily invested in Rockwell’s automation ecosystem.

Final Thoughts – AI for Manufacturing

These five AI solutions represent the leading edge of manufacturing optimization:

-

KaizenUp puts people at the center, giving frontline leaders AI tools for safety, problem-solving, and continuous improvement.

-

Siemens Insight Hub connects factories worldwide with predictive analytics and digital twins.

-

IBM Maximo delivers enterprise-scale asset management powered by AI.

-

ABB Ability optimizes heavy industries with energy-efficient AI applications.

-

Rockwell Automation provides integrated analytics and cloud connectivity for modern factories.

Together, they demonstrate how AI is shaping the future of manufacturing—by making processes faster, safer, more reliable, and more human-centered.

I am highly experienced marketing professional with over 4 years of experience in the industry. With a strong background in marketing strategies for both B2C and B2B companies. I am skilled in well-versed in the latest digital marketing trends and technologies.

An experienced lean manager with a deep understanding of lean management principles and techniques. I have strong leadership skills, and I am able to motivate and lead teams to achieve results. I am able to communicate effectively, and are skilled at building consensus and working with cross-functional teams. In addition to my experience and expertise, I am also committed to continuous learning and improvement. I am always looking for ways to learn and grow, and I am willing to try new approaches and techniques in order to achieve success.